| Industry | Introduce |

| Aerospace | Carbon fiber is the material basis of the modern aerospace industry and is irreplaceable. The application of carbon fiber composite materials in spacecraft has matured day by day, and it is an indispensable key material for spacecraft to achieve lightweight, miniaturization and high performance. The lightweight and high-strength properties of carbon fiber are widely used in the body of military helicopters, fighters and UAVs, as well as the main wing and tail, brake pads and skins, etc., which have played a significant weight reduction effect. At present, carbon fiber materials are used in military aircraft. The application has developed from non-load bearing and secondary bearing structure to main bearing structure, and the coverage is getting larger and larger.

At present, Olymspan has developed a series of products such as carbon fiber-phenolic heat-resistant composite materials, high-strength and high-toughness carbon fiber-epoxy composite materials, and high-temperature carbon fiber composite materials, which are mainly used for non-stressed parts of aircraft, such as rudder surface, spoiler, fairing, horizontal tail, vertical tail, wing, nose, fuselage, etc... |

| Automobile industry | The British Material Systems Laboratory's research on the use of materials to reduce the weight of automobiles and reduce production costs shows that for every 10% reduction in automobile quality, fuel consumption can be reduced by 6%. Among the existing materials, carbon fiber composites' lightweight effect is the best, coupled with the rapid development of automobile design and composite material technology, all these have made the application speed of carbon fiber composites in the field of automobile manufacturing far exceed people's expectations. |

| Medical devices | In the field of medical devices, because of the full transmittance of carbon fiber composites to X-rays, they are used to manufacture mobile platforms for X-ray inspection instruments. Due to the excellent mechanical properties of carbon fiber composites, they are used in the manufacture of medical devices for orthopedics and organ transplantation, as well as for the manufacture of rehabilitation products such as prostheses and orthotics. |

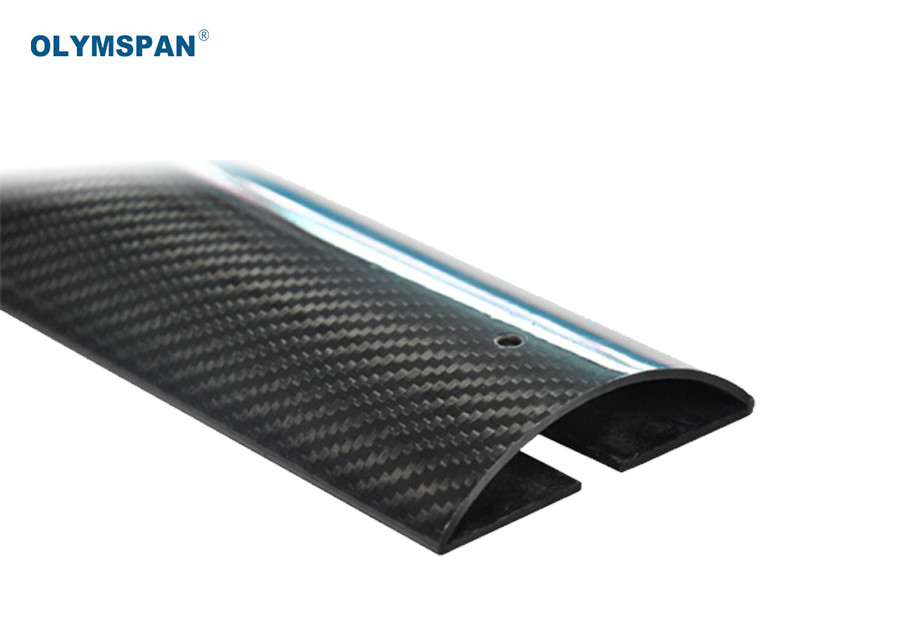

| Rail transport | Lightweight is a key technology to reduce the energy consumption of train operation. Rail trains made of metal have high body strength, but their mass and hardness are high. Carbon fiber composite is a high-quality material for the body of a new generation of high-speed rail trains. It can not only make the rail train body lightweight, but also improve high-speed running performance, reduce energy consumption, reduce environmental pollution, and enhance safety. At present, the application trends of carbon fiber composites in the field of rail vehicles include: extending from non-load-bearing structural parts such as car interiors and interior equipment to load-bearing components such as car bodies and frames; The development of large-scale structures such as, driver’s cabs, and vehicle bodies; hybrid structures of metal and composites are the mainstay, and the amount of carbon fiber composites has been greatly increased.

The application of Olymspan's products in the lightweight rail transit mainly focuses on the body and interior decoration, such as Brake pads, diversion shield and other parts. |

| Military industry | Modern warfare weapons and equipment are developing rapidly toward low energy consumption, large payload, stealth, and high mobility, and higher requirements are also placed on the materials used to manufacture weapons. Carbon fiber composite materials, known as "black gold", are widely used in national defense and military industries due to their excellent material properties. The use of carbon fiber materials to create better-performing weapons and equipment has long become a new battlefield where military powers compete. |

| Textile machinery | There are two main problems in the development of textile machinery in China: one is the low operating speed of textile machinery equipment, and the other is that the average energy consumption of the equipment is relatively high. In order to further reduce energy consumption and improve production efficiency, textile machinery began to gradually use carbon fiber materials in parts. Carbon fiber is light in weight, but high strength. It is an ideal material for light weight of medium and high-end machinery. Olymspan applies lightweight and high-strength carbon fiber composites to textile machinery, which will vigorously promote the equipment of textile machinery enterprises to move towards low cost, low energy consumption and high efficiency. |

| Sports industry | Sports and leisure products are the first application areas for carbon fiber composite materials to enter the market. With the improvement of cost performance, this field has formed a stable demand for carbon fiber composite materials. Skis, ski sticks, ice hockey sticks, tennis rackets and bicycles are typical applications of carbon fiber composite materials in sports and leisure products

The carbon fiber sports equipment produced by Olymspan has the advantages of light weight, high specific strength and high specific modulus, high fatigue strength, low thermal expansion coefficient, good damage safety performance, and good damping. Products include: poles, bows, golf clubs, tennis rackets, bicycles, snowboards, kayaks, etc. |

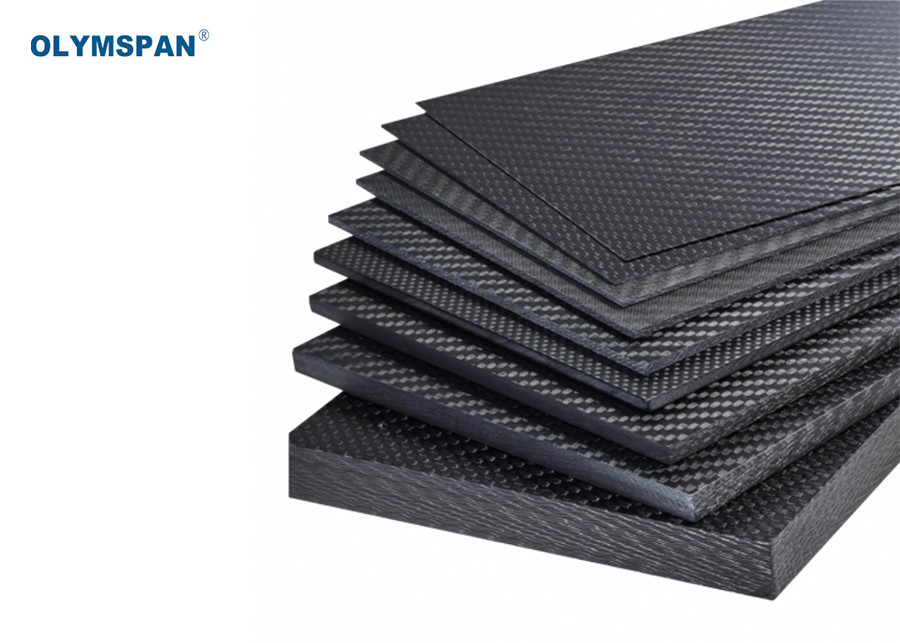

| Industrial equipment | Carbon fiber composite parts are lightweight, thin, antistatic and anti-electromagnetic. They are widely used in electronic information products such as notebook computers, liquid crystal projectors, cameras, optical lenses and large liquid crystal display panels. In addition, the carbon fiber composites has excellent tear resistance and can also be used to manufacture bearings, rollers, pipes and other products. Its strength is the same as that of steel products, but the quality can be greatly reduced.

Olymspan can produce lightweight and high-strength carbon fiber composite equipment parts and special-shaped parts according to customer needs. And can also produce lightweight and high-strength carbon fiber composite robot arms, connectors, mechanical equipment transport arms and other products according to our customer needs. |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!