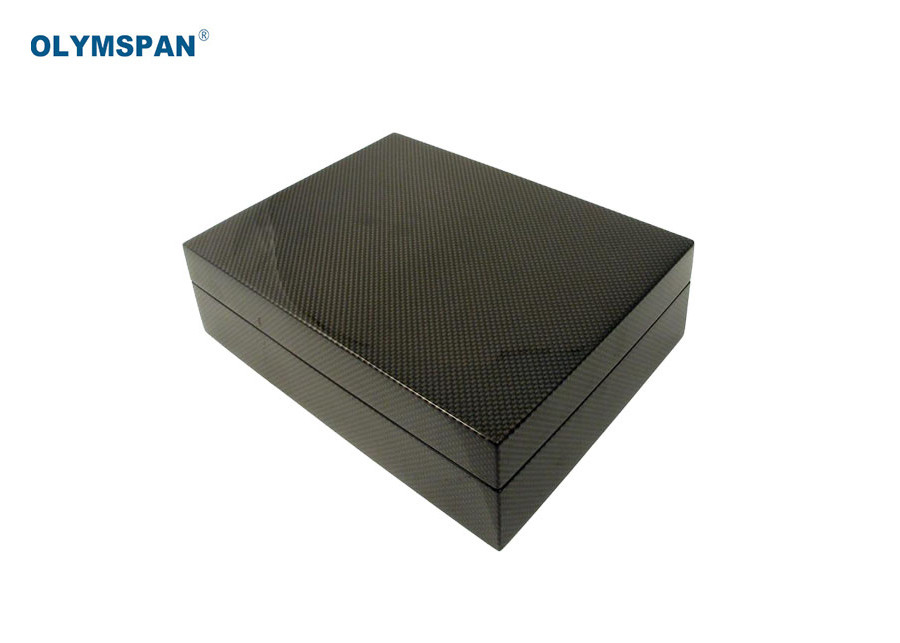

Low price smooth carbon fibre manufactured products made in China

Our technology:

1, Pre-preg / Autoclave

Pre-preg is the “top class” fabric which during the manufacturing process undergoes impregnation with resin mixed with hardener. The resin provides protection against damage and imparts the required viscosity to ensure fabric adherence to the mold surface.

Pre-preg type carbon fiber has applications in Formula 1 racing cars, as well as in the manufacture of carbon fiber elements of sports bicycles.

When is it used? For manufacture of premium quality products of complex design that have low weight and outstanding appearance.

Our autoclave generates working pressure of 8 bar that provides optimal strength of manufactured products as well as a perfect appearance of composites without any trapped air defects.

After manufacture, components undergo varnishing in the paint spray booth.

2, Resin infusion

Resin infusion is a process whereby fabric in moulds is sealed with film/butyl tape and filled with a liquid resin. When the resin solidifies, the solid resin matrix binds the assembly of materials into a unified rigid composite.

This technique has applications in the manufacture of carbon sheets and other large items that have a moderately complex shape.

3, Manual laminating

Manufacture of high quality carbon fiber products requires costly technology. Dexcraft is one of the few companies that manufacture products using proprietary technologies of manual laminating that ensure high quality composites.

Our products manufactured using manual laminating technology present no defects related to air bubbles in the carbon fiber visual layer. Thanks to in-mold coating technology, all manufactured elements are resistant to UV as soon as they are removed from the mold (eliminating further spraying).

4, Customized techniques

To meet clients’ requirements and needs, we developed proprietary solutions that enable manufacture of unique products. For many years we built our reputation as a supplier who provides solutions where others failed.

We also offer expertise in microsphere and bladder inflation.

Application of carbon fibre:

1, Sports industry: Sports and leisure products are the first application areas for carbon fiber composite materials to enter the market. With the improvement of cost performance, this field has formed a stable demand for carbon fiber composite materials. Skis, ski sticks, ice hockey sticks, tennis rackets and bicycles are typical applications of carbon fiber composite materials in sports and leisure products

The carbon fiber sports equipment produced by Olymspan has the advantages of light weight, high specific strength and high specific modulus, high fatigue strength, low thermal expansion coefficient, good damage safety performance, and good damping. Products include: poles, bows, golf clubs, tennis rackets, bicycles, snowboards, kayaks, etc.

2, Aerospace: Carbon fiber is the material basis of the modern aerospace industry and is irreplaceable. The application of carbon fiber composite materials in spacecraft has matured day by day, and it is an indispensable key material for spacecraft to achieve lightweight, miniaturization and high performance. The lightweight and high-strength properties of carbon fiber are widely used in the body of military helicopters, fighters and UAVs, as well as the main wing and tail, brake pads and skins, etc., which have played a significant weight reduction effect. At present, carbon fiber materials are used in military aircraft. The application has developed from non-load bearing and secondary bearing structure to main bearing structure, and the coverage is getting larger and larger.

At present, Olymspan has developed a series of products such as carbon fiber-phenolic heat-resistant composite materials, high-strength and high-toughness carbon fiber-epoxy composite materials, and high-temperature carbon fiber composite materials, which are mainly used for non-stressed parts of aircraft, such as rudder surface, spoiler, fairing, horizontal tail, vertical tail, wing, nose, fuselage, etc...

3, Rail transport: Lightweight is a key technology to reduce the energy consumption of train operation. Rail trains made of metal have high body strength, but their mass and hardness are high. Carbon fiber composite is a high-quality material for the body of a new generation of high-speed rail trains. It can not only make the rail train body lightweight, but also improve high-speed running performance, reduce energy consumption, reduce environmental pollution, and enhance safety. At present, the application trends of carbon fiber composites in the field of rail vehicles include: extending from non-load-bearing structural parts such as car interiors and interior equipment to load-bearing components such as car bodies and frames; The development of large-scale structures such as, driver’s cabs, and vehicle bodies; hybrid structures of metal and composites are the mainstay, and the amount of carbon fiber composites has been greatly increased.

The application of Olymspan's products in the lightweight rail transit mainly focuses on the body and interior decoration, such as Brake pads, diversion shield and other parts.

4, Automobile industry: The British Material Systems Laboratory's research on the use of materials to reduce the weight of automobiles and reduce production costs shows that for every 10% reduction in automobile quality, fuel consumption can be reduced by 6%. Among the existing materials, carbon fiber composites' lightweight effect is the best, coupled with the rapid development of automobile design and composite material technology, all these have made the application speed of carbon fiber composites in the field of automobile manufacturing far exceed people's expectations.

5, Medical devices: In the field of medical devices, because of the full transmittance of carbon fiber composites to X-rays, they are used to manufacture mobile platforms for X-ray inspection instruments. Due to the excellent mechanical properties of carbon fiber composites, they are used in the manufacture of medical devices for orthopedics and organ transplantation, as well as for the manufacture of rehabilitation products such as prostheses and orthotics.

Welcome you to visit our workshop to see our products and production lines!

| Why purchase carbon fiber products from Olymspan Composites: |

| 1. Purchase carbon fiber car parts directly from a professional manufacturer . |

| 2. Strict control on materials , high quality carbon fiber pre-preg and epoxy resin . |

| 3. Autoclave technology and experts of carbon fiber products. |

| 4. Thousand of carbon fiber parts, covering different industry. |

| 5. Strength on new carbon fiber products development . OEM & ODM are welcomed. |

| 6. Excellent pre and post sales service. |

FAQ:

Q: what is the proceesing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well, quote the price to clients after got the 2d or 3d drawings within 2 hours.

Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote.

Q: Do you do the surface treatments please ?

A:yes, we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting.

Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping.

Q: How long can it be delivery ?

A: Delivery from 7-50days that depends on the parts.

Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are also acceptable.

Company and products:

For more details, welcome to contact us at any time, looking forward to your kind response!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!