Purchase carbon fiber OEM high quality automobile parts supply in China

Welcome you to visit our workshop to see our products and production lines!

| Why purchase carbon fiber products from Olymspan Composites: |

| 1. Purchase carbon fiber car parts directly from a professional manufacturer . |

| 2. Strict control on materials , high quality carbon fiber pre-preg and epoxy resin . |

| 3. Autoclave technology and experts of carbon fiber products. |

| 4. Thousand of carbon fiber parts, covering different industry. |

| 5. Strength on new carbon fiber products development . OEM & ODM are welcomed. |

| 6. Excellent pre and post sales service. |

Application of carbon fiber materials in automobiles

1. Application on car body.

In traditional automobile production, metal materials such as steel account for a large proportion of the car body. If carbon fiber composite materials are used to manufacture automobile bodies and chassis, the weight of the entire automobile can be reduced by 40% to 60%, which is equivalent to 1/3 of the steel structure. 1/6. Its tensile strength is 7-8 times that of similar steel structures, at the same time, the safety and impact resistance of the car body can also be guaranteed. In addition, because carbon fiber materials are easy to process into various complex structures, the integration of new energy vehicle bodies can be realized. To a large extent, the manufacturing process of the process is shortened, thereby reducing part of the manufacturing cost.

2. Application in automobile hub.

The car hub is one of the important parts of the car. It plays a vital role in the safe driving of the car. The hub has to bear the weight of the car itself and the load of the car. In addition, the hub has to transmit drive and torque. Therefore, the quality of the car hub is very high. Carbon fiber composite material has excellent heat resistance, fatigue resistance and mechanical properties, and can be used as a substitute for metal materials as a material for making car hubs to meet the requirements of high strength, good impact resistance and good heat resistance. At the same time, the carbon fiber composite material for the hub can reduce the quality of the hub, and help reduce the inertia of the wheel rotation, and start the car, stop the car and turn the speed faster.

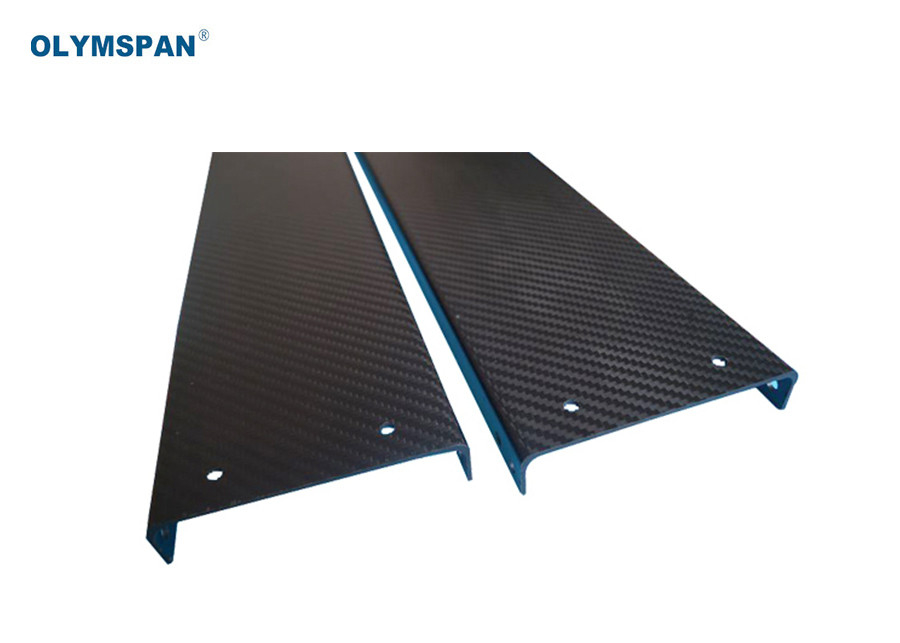

3. Application in interior and exterior decoration of automobiles

Good energy absorption performance is a major advantage of carbon fiber composite materials. Therefore, when a car is facing an impact, it can well absorb the huge impulse generated by it, and play a good cushioning and shock absorption effect. At the same time, it reduces the debris generated by the impact, which greatly improves the safety performance of the car. The interior and exterior trims on the car are made of carbon fiber composite materials, which can greatly reduce the production cost of the car and the user’s use cost. First of all, the use of carbon fiber composite materials can realize the lightweight of the car. In addition, because the carbon fiber composite material is easy to process and shape, it simplifies the car’s The production process of parts and components, thereby greatly reducing the production cost in the process of processing parts, maintenance and assembly.

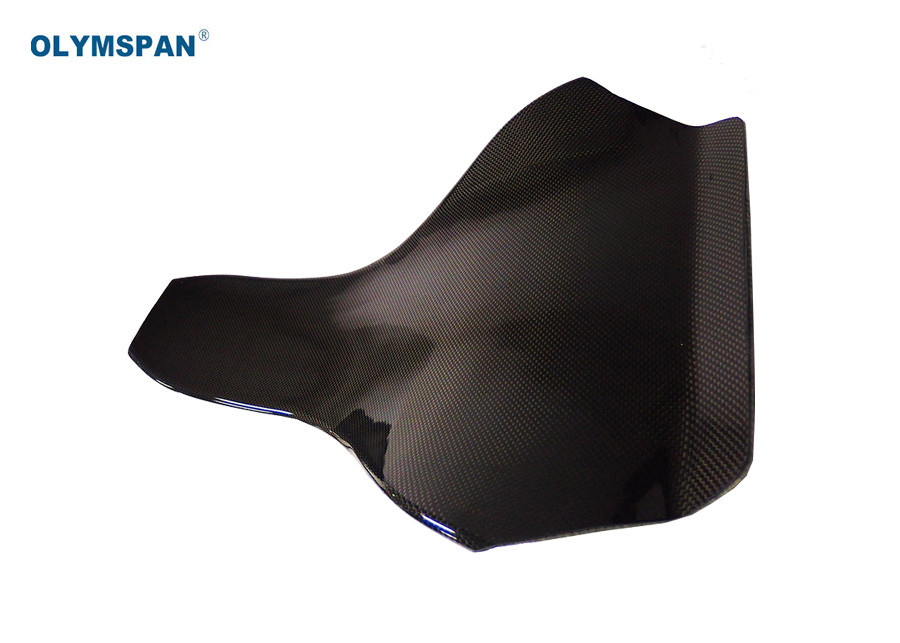

4. Application in automobile air intake system.

The car's air intake system uses carbon fiber composite materials, which can be easily processed into complex shapes with various required curved surfaces due to good processing performance. Moreover, the smooth surface of the carbon fiber composite materials can effectively improve the car's air intake efficiency. In addition, it can also reduce the quality of the air intake system, thereby reducing the quality of the entire vehicle and achieving a lightweight effect.

5. The application of carbon fiber in the brake system.

Automobile brake linings mainly use asbestos materials, which are easy to friction and generate high temperatures during braking, and thermal degradation of performance occurs, and the asbestos dust produced is carcinogenic. Carbon fiber composite material has high specific strength, good wear resistance and good heat resistance. It is used in automobile brake pads and can be used as a substitute for asbestos. The carbon fiber brake disc can reduce the vehicle speed from 300KM/h to 50Km/h within 50m. Carbon fiber brake discs can withstand high temperatures of 2500°C with stable performance.

The advantage of carbon fibre auto parts:

1. The density is small, which can meet the requirements of lightweight cars, thereby achieving energy saving and emission reduction, and reducing environmental pollution. It is an environmentally friendly material.

2. Good plasticity. The carbon fiber composite material has good plasticity. It can be easily processed into various complex shapes according to the needs of use, including some curved shapes that are difficult to process by metal materials, which is conducive to the realization of the integral structure of the car body. . For example, if all seats in the car are designed as a whole, if metal materials are used, about 50-60 parts need to be welded. The parts of carbon fiber composite materials should be greatly reduced, which simplifies the production process and greatly improves Improve work efficiency.

3. Carbon fiber composite material has good energy absorption performance. When applied to the car body, it can play a role in cushioning and absorbing energy when impacted, and the safety performance of the car can be greatly improved.

Company and pictures:

FAQ:

Q: what is the proceesing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well, quote the price to clients after got the 2d or 3d drawings within 2 hours.

Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote.

Q: Do you do the surface treatments please ?

A:yes, we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting.

Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping.

Q: How long can it be delivery ?

A: Delivery from 7-50days that depends on the parts.

Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are also acceptable.

Q: Do you have any MOQ limit?

A: Our MOQ is 1 pcs.

Q: Can you accept mixed batch of different products?

A: Yes, we are support different product mix wholesale.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!