Drawing design carbon fibre composites manufacture mobile medical devices

Application of carbon fibre in medical device:

1, Superconducting magnet components

Magnetic resonance imaging has become a common medical examination method in major hospitals. The core superconducting magnet of the device needs to be at a very low temperature to produce a higher magnetic field. The internal components of nuclear magnetic resonance equipment need to exhibit stable performance at low temperatures in liquid nitrogen. Carbon fiber materials can achieve stable mechanical properties at extremely low temperatures. Therefore, carbon fiber composite materials are suitable for making mechanical components at the temperature of nuclear magnetic resonance.

2, Carbon fiber prosthesis

The prosthesis made of carbon fiber composite material has high strength and light weight, which makes the function of the prosthesis more perfect. At the same time, its feet can also change the appearance according to the occasion, such as high heels for banquets, casual shoes for daily life, yoga shoes for sports and so on.

At present, carbon fiber is widely used in human prostheses such as knee joints, ankle joints, feet, connecting tubes, and receiving cavities. It can be designed and processed according to the local force requirements of the prosthesis to meet the needs of high-frequency use.

3, X-ray inspection equipment

X-ray detection is commonly used in medical inspection vehicles. X-ray flat panel detectors are multi-functional high-resolution X-ray flat-panel imaging equipment. Carbon fiber absorbs less radiation, has strong wave-transmitting performance, can conduct micro-current, can reduce the voltage and reduce the ray energy, make the detector appear more clear, and reduce the power consumption, reduce the radiation, and greatly reduce the harm to doctors and patients. Compared with the traditional aluminum plate, the advantages are obvious.

4, Medical CT bed board

Carbon fiber composite material has stable chemical properties and strong corrosion resistance. Even if it is in long-term contact with common medical items such as alcohol, drugs, blood, it will not corrode, and it is easy to clean and transfer. It is an excellent material for making medical bed boards.

The carbon fiber material medical bed board is mostly used on the radiographic testing bed. The bed board itself can achieve no refraction of rays at any angle, high transmittance, and clearer display. It can meet the requirements of strength and rigidity with less materials. Compared with the traditional medical bed board, its weight can be reduced by about 45%.

5, dental restoration

Studies on the physical and chemical properties and biological properties of carbon fiber posts have shown that carbon fiber posts have mechanical properties that are more compatible with dental tissues, and its elastic modulus similar to dentin can make stresses more evenly distributed along the post, which is beneficial for protection Tooth root; at the same time, it has many advantages such as good biocompatibility and corrosion resistance, easy removal, and convenience for secondary restoration.

6, Carbon fiber wheelchair

The density of carbon fiber is only 1.7g/cm3, and accessories of the same specification are more than half lighter than aluminum alloy materials, but the strength is much greater. In addition, carbon fiber also has strong corrosion resistance, and a considerable proportion of wheelchair patients face Incontinence of urine and feces and frequent contact with injection liquids and other issues, in this case, the accessories of carbon fiber composite materials exhibit durability that is unmatched by ordinary metal materials.

At present, carbon fiber composite materials are mainly used in accessories such as armrests, arm rests, foot rests, leg rests, backrests, skirt boards, and frame tubes. Most of these accessories can be adjusted in height. Carbon fiber composite materials are easy to assemble with the wheelchair through mechanical connections. The most important thing is that after the use of carbon fiber composite materials for these accessories, the overall weight of the wheelchair has been significantly reduced, and as a component with a high frequency of use, it has also become more durable.

Our technology:

1, Prepreg / Autoclave

Pre-preg is the “top class” fabric which during the manufacturing process undergoes impregnation with resin mixed with hardener. The resin provides protection against damage and imparts the required viscosity to ensure fabric adherence to the mold surface.

Pre-preg type carbon fiber has applications in Formula 1 racing cars, as well as in the manufacture of carbon fiber elements of sports bicycles.

When is it used? For manufacture of premium quality products of complex design that have low weight and outstanding appearance.

Our autoclave generates working pressure of 8 bar that provides optimal strength of manufactured products as well as a perfect appearance of composites without any trapped air defects.

After manufacture, components undergo varnishing in the paint spray booth.

2, Resin infusion

Resin infusion is a process whereby fabric in moulds is sealed with film/butyl tape and filled with a liquid resin. When the resin solidifies, the solid resin matrix binds the assembly of materials into a unified rigid composite.

This technique has applications in the manufacture of carbon sheets and other large items that have a moderately complex shape.

3, Manual laminating

Manufacture of high quality carbon fiber products requires costly technology. Dexcraft is one of the few companies that manufacture products using proprietary technologies of manual laminating that ensure high quality composites.

Our products manufactured using manual laminating technology present no defects related to air bubbles in the carbon fiber visual layer. Thanks to in-mold coating technology, all manufactured elements are resistant to UV as soon as they are removed from the mold (eliminating further spraying).

4, Customized techniques

To meet clients’ requirements and needs, we developed proprietary solutions that enable manufacture of unique products. For many years we built our reputation as a supplier who provides solutions where others failed.

We also offer expertise in microsphere and bladder inflation.

FAQ:

Q: what is the proceesing for the quote ?

A: We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well, quote the price to clients after got the 2d or 3d drawings within 2 hours.

Q: How is the next ?

A: We will send the cost to you and get your confirmations for the quote.

Q: Do you do the surface treatments please ?

A:yes, we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting.

Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping.

Q: How long can it be delivery ?

A: Delivery from 7-50days that depends on the parts.

Q: Can I have a sample order?

A: Yes, we welcome sample order to test and check quality. Mixed samples are also acceptable.

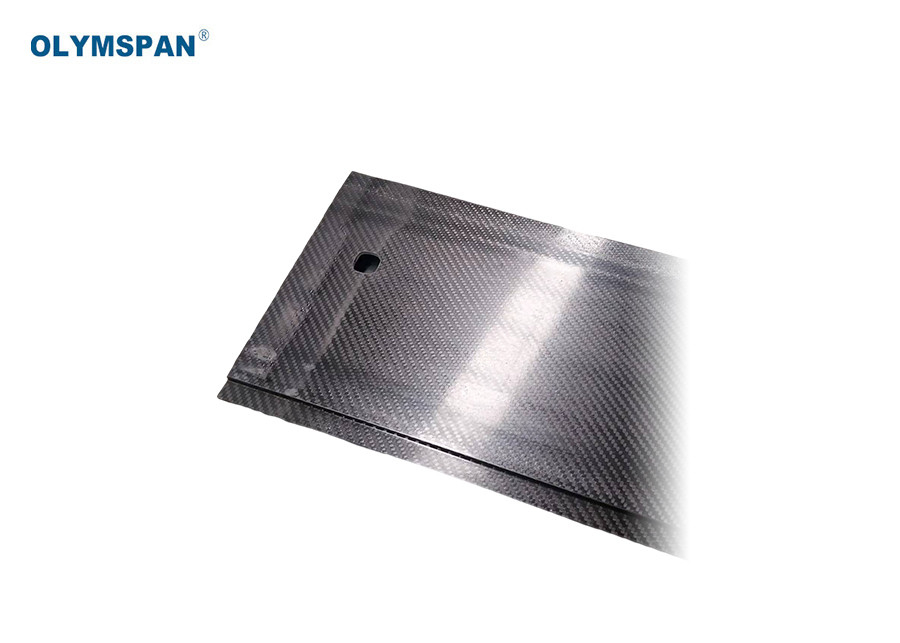

Pictures of our company and products:

For more details, welcome to contact us, looking forward to your kind response!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!