Manuafcturing aerospace carbon fiber parts to reduce energy consumption

Application of carbon fiber products:

1, Aerospace

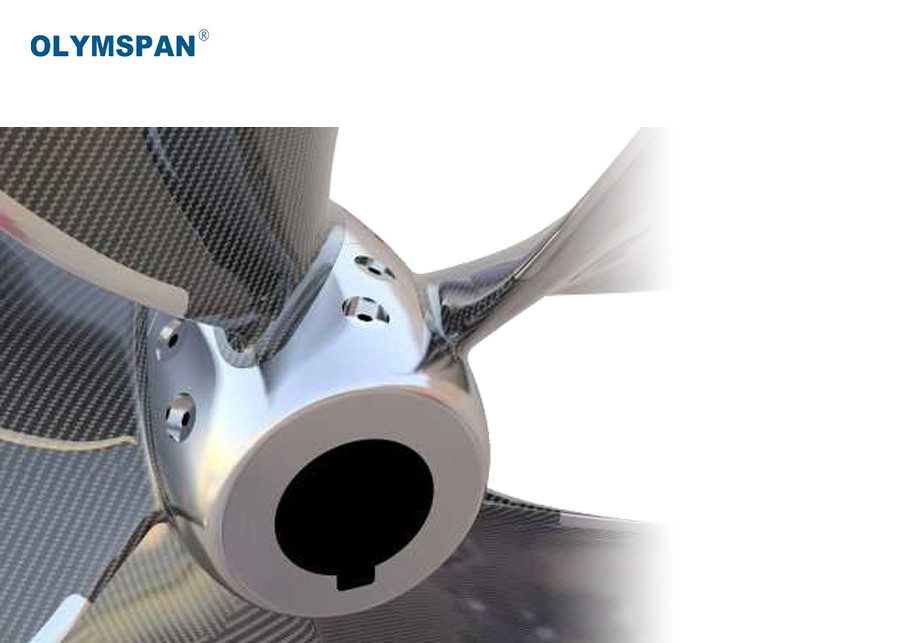

Carbon fiber is the material basis of the modern aerospace industry and is irreplaceable. The application of carbon fiber composite materials in spacecraft has matured day by day, and it is an indispensable key material for spacecraft to achieve lightweight, miniaturization and high performance. The lightweight and high-strength properties of carbon fiber are widely used in the body of military helicopters, fighters and UAVs, as well as the main wing and tail, brake pads and skins, etc., which have played a significant weight reduction effect. At present, carbon fiber materials are used in military aircraft. The application has developed from non-load bearing and secondary bearing structure to main bearing structure, and the coverage is getting larger and larger.

At present, Olymspan has developed a series of products such as carbon fiber-phenolic heat-resistant composite materials, high-strength and high-toughness carbon fiber-epoxy composite materials, and high-temperature carbon fiber composite materials, which are mainly used for non-stressed parts of aircraft, such as rudder surface, spoiler, fairing, horizontal tail, vertical tail, wing, nose, fuselage, etc...

2, Rail transport

Lightweight is a key technology to reduce the energy consumption of train operation. Rail trains made of metal have high body strength, but their mass and hardness are high. Carbon fiber composite is a high-quality material for the body of a new generation of high-speed rail trains. It can not only make the rail train body lightweight, but also improve high-speed running performance, reduce energy consumption, reduce environmental pollution, and enhance safety. At present, the application trends of carbon fiber composites in the field of rail vehicles include: extending from non-load-bearing structural parts such as car interiors and interior equipment to load-bearing components such as car bodies and frames; The development of large-scale structures such as, driver’s cabs, and vehicle bodies; hybrid structures of metal and composites are the mainstay, and the amount of carbon fiber composites has been greatly increased.

The application of Olymspan's products in the lightweight rail transit mainly focuses on the body and interior decoration, such as Brake pads, diversion shield and other parts.

3, Industrial equipment

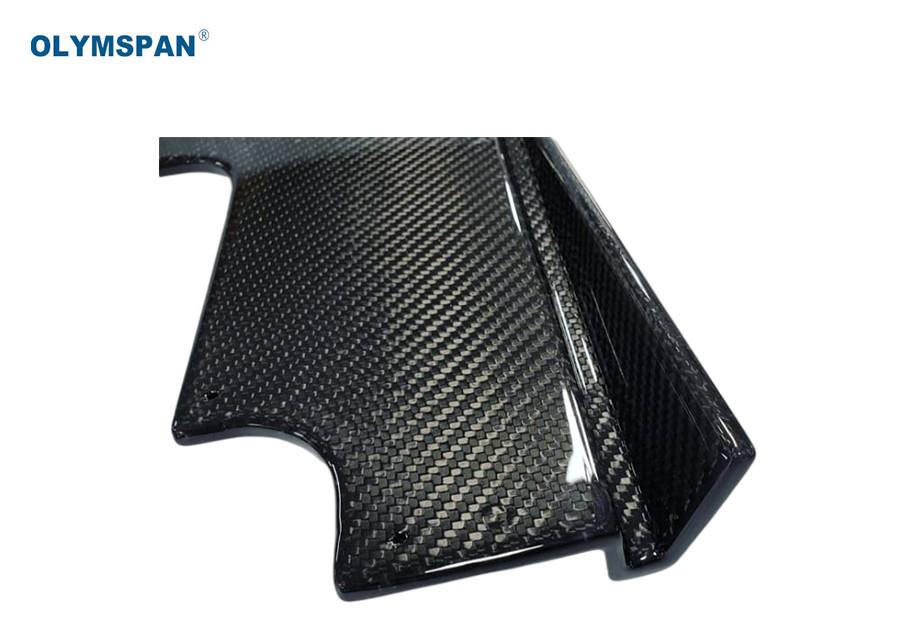

Carbon fiber composite parts are lightweight, thin, antistatic and anti-electromagnetic. They are widely used in electronic information products such as notebook computers, liquid crystal projectors, cameras, optical lenses and large liquid crystal display panels. In addition, the carbon fiber composites has excellent tear resistance and can also be used to manufacture bearings, rollers, pipes and other products. Its strength is the same as that of steel products, but the quality can be greatly reduced.

Olymspan can produce lightweight and high-strength carbon fiber composite equipment parts and special-shaped parts according to customer needs. And can also produce lightweight and high-strength carbon fiber composite robot arms, connectors, mechanical equipment transport arms and other products according to our customer needs.

What we do?

We supply a wide range of services related to carbon fiber composites: from manufacture of molds, fabric cutting, through to manufacture of composite elements, machine cutting of fine details, and finally varnishing, assembly and quality control.

We possess know-how and expertise in all techniques related to carbon product manufacture. To every client we offer the perfect production technology that meets their needs and ensures an end product of high quality.

Why choose us!

1, Carbon fiber has the characteristics of light weight and high strength, which can be applied to various automobile, which can help you improve your product.

2, Our carbon fiber accessories can be used for product modification to meet various needs of your customers.

3, We are a professional carbon fiber customization factory that can give you the best price and best quality.

4, As long as there are drawings, you can customize the accessories you need, and our technicians will always support online.

5, The manufacture of carbon fiber parts requires a lot of time cost and labor cost, we can save them for you

6, Carbon fiber products are becoming more and more popular in the high-end market.

Product Pictures:

FAQ:

| Question |

Answer |

| What is the proceesing for the quote? |

We can quote from your 3d formats like IGS,STP,PARASOLID etc and 2D drawings as well, quote the price to clients after got the 2d or 3d drawings within 2 hours. |

| How is the next? |

We will send the cost to you and get your confirmations for the quote. |

| Do you do the surface treatments please? |

Yes, we do the surface treatments, for instance: chromated, powder coating, Anodizing, laser etching as well as painting.

|

| What is the quality Control before shipping? |

We have QC department for the quality control before shipping. |

| How long can it be delivery? |

Delivery from 7-50days that depends on the parts.

|

| Can I have a sample order? |

Yes, we welcome sample order to test and check quality. Mixed samples are also acceptable.

|

| Can you provide container packed in wooden cases if I order more products? |

Yes, we are can provide a set of wooden packaging products, but only in big quantity. |

| We want to visit your company? |

No problem, we are a production and processing enterprises, look forward to your arrival and we will lead you to visit our office and processing factory. |

Our Company:

For more details, welcome to contact me, looking forward to be your partner!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!