CE certified carbon fiber cnc service automobile production OEM&ODM suppport

Why choose carbon fiber material?

Carbon fiber is a material of many unique properties including extreme strength and light weight that lends itself to original and highly attractive designs.

Carbon is perfect where a product must have high strength and low weight.

A composite made of carbon fibre while keeping the same thickness is about 30-40% lighter than an element made of aluminum. In comparison a composite of the same weight made of carbon fiber is 5 times more rigid than steel.

Add the practically zero thermal expansion of carbon and its exceptionally attractive premium quality appearance and we can easily understand why it is so popular with applications in many industries to create devices, optics and general products.

Application of carbon fiber materials in automobiles

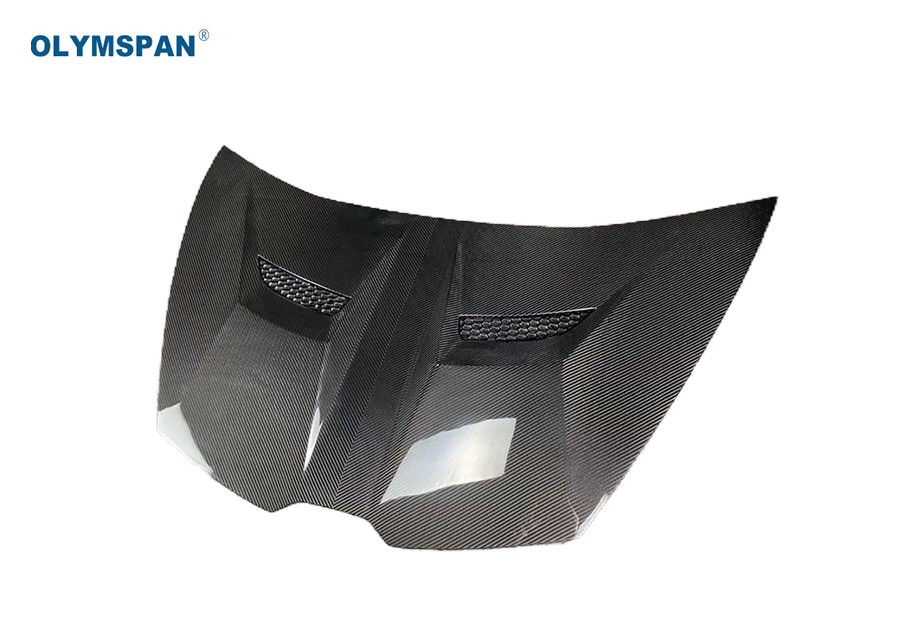

1. Application on car body.

In traditional automobile production, metal materials such as steel account for a large proportion of the car body. If carbon fiber composite materials are used to manufacture automobile bodies and chassis, the weight of the entire automobile can be reduced by 40% to 60%, which is equivalent to 1/3 of the steel structure. 1/6. Its tensile strength is 7-8 times that of similar steel structures, at the same time, the safety and impact resistance of the car body can also be guaranteed. In addition, because carbon fiber materials are easy to process into various complex structures, the integration of new energy vehicle bodies can be realized. To a large extent, the manufacturing process of the process is shortened, thereby reducing part of the manufacturing cost.

2. Application in automobile hub.

The car hub is one of the important parts of the car. It plays a vital role in the safe driving of the car. The hub has to bear the weight of the car itself and the load of the car. In addition, the hub has to transmit drive and torque. Therefore, the quality of the car hub is very high. Carbon fiber composite material has excellent heat resistance, fatigue resistance and mechanical properties, and can be used as a substitute for metal materials as a material for making car hubs to meet the requirements of high strength, good impact resistance and good heat resistance. At the same time, the carbon fiber composite material for the hub can reduce the quality of the hub, and help reduce the inertia of the wheel rotation, and start the car, stop the car and turn the speed faster.

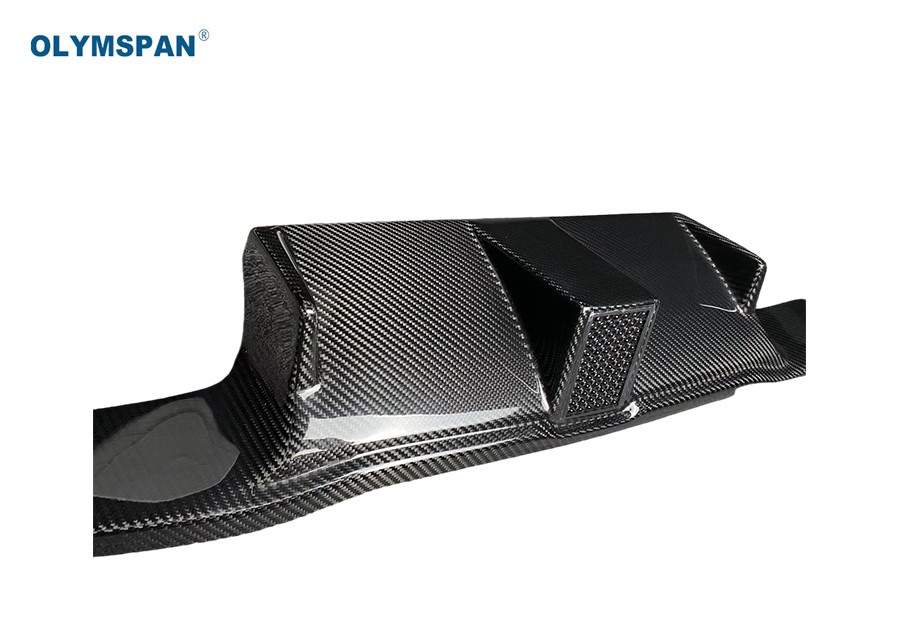

3. Application in interior and exterior decoration of automobiles

Good energy absorption performance is a major advantage of carbon fiber composite materials. Therefore, when a car is facing an impact, it can well absorb the huge impulse generated by it, and play a good cushioning and shock absorption effect. At the same time, it reduces the debris generated by the impact, which greatly improves the safety performance of the car. The interior and exterior trims on the car are made of carbon fiber composite materials, which can greatly reduce the production cost of the car and the user’s use cost. First of all, the use of carbon fiber composite materials can realize the lightweight of the car. In addition, because the carbon fiber composite material is easy to process and shape, it simplifies the car’s The production process of parts and components, thereby greatly reducing the production cost in the process of processing parts, maintenance and assembly.

4. Application in automobile air intake system.

The car's air intake system uses carbon fiber composite materials, which can be easily processed into complex shapes with various required curved surfaces due to good processing performance. Moreover, the smooth surface of the carbon fiber composite materials can effectively improve the car's air intake efficiency. In addition, it can also reduce the quality of the air intake system, thereby reducing the quality of the entire vehicle and achieving a lightweight effect.

5. The application of carbon fiber in the brake system.

Automobile brake linings mainly use asbestos materials, which are easy to friction and generate high temperatures during braking, and thermal degradation of performance occurs, and the asbestos dust produced is carcinogenic. Carbon fiber composite material has high specific strength, good wear resistance and good heat resistance. It is used in automobile brake pads and can be used as a substitute for asbestos. The carbon fiber brake disc can reduce the vehicle speed from 300KM/h to 50Km/h within 50m. Carbon fiber brake discs can withstand high temperatures of 2500°C with stable performance.

For more details, welcome to contact me! Looking forward to be your partner!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!